Description

Liquid Painting Booth

To accomplish the pollution-less environment. NSW has designed and developed very efficient and effective liquid spray booths, which offer adequate flow of clean air. The standard designs range from an economical model, to an excellent performer in quality painting. Liquid paint Booth with disposable filters is an economical choice for low volume Spray Painting operations. Well designed filtration/ separator system offers highest efficiency of paint collection

NSW Offers – Booths with various set of combinations of following features & specifications.

- An open booth for general purpose.

- A closed pressurized booth with controlled air quality & velocity.

- Dry booth with paint arresting filters

- Wet booth with Ventury and scrubber

- Side draft booth

- Down draft booth

|

|

| Off Line Spray Paint Booth | Pressurised Booth with Paint Kitchen |

|

Wet Booth: – These booths prove to be extremely efficient means of removing paint particles from the air by using waters a filtration media. A water wall informed in front of the article by the means of the pump. The over sprayed paint in the air, is pulled towards this water wall and gets mixed in the water by using efficient design of Ventury. These paint particles and resins then converts into the non sticky sludge in the water tank making it easy to dispose off. Scrubber is used for the treatment of the air before being exhausted in the atmosphere.

|

Filteration System in Booth Filteration System in Booth |

Side draft booth: –These booths are well suited for small and medium size components to be painted. Basically these booths are closed from all the sides except one behind the painter. The air travels from the back of the operator towards the product and is exhausted from the other side after being treated.This kind of air pattern is the open booths and can also be provided in the closed booths with the opening at the top behind the operator. |

![]()

Down draft booth: – These booths are especially useful for parts and components which have large sizes, weight and are difficult to handle like crane, tractor, agricultural machines, automobiles, or any kind. All sides are closed except the top, to take the fresh air vertically from top towards the bottom.

Bench paint booth: – These paint booths are small in size, which are generally used in laboratories or for batch production of very small and light wt products in low quantities.

![]()

BOOTH WITH FILTERS AND PLANUM CHAMBER

A Process, in which very high quality painting standards is required, there the booths with very fine filters, on the top, can be provided for the dust free supply of air inside the booth.

These Pressurizes booths are enclosed chambers which are designed either for side or for down draft airflow flow system. The air is thrown vertically down wards from plenum chamber located on the ceiling towards the floor in the working area, and then is exhausted outside after passing through the scrubber.

P.D.C Booth: –They are a closed room where painting and drying process is done in the same chamber These are the batch type, dry paint booths with the provision of low temperature heating system. The products are placed inside the booth for the painting process. After the painting is done the heating system is

switched on for the baking of the paint (Up to 80 Deg. C). There are filters provided on both in-let as well as on the outlet ducts of the chamber. These painting cum drying booths are the mainly used for large sized products like car, crane, train bogies, etc.

|

|

|

| Temp. & Humidity controlled with 5 micron filtration sir supply unit |

Open type Dry booth | Close pressurized booth with temperature & humidity controlled |

| |

|

|

|

|

|

| Close pressurised booth | Over Head Type Painting Plant for Auto-mobile Parts |

Painting plant for metal parts |

|

|---|

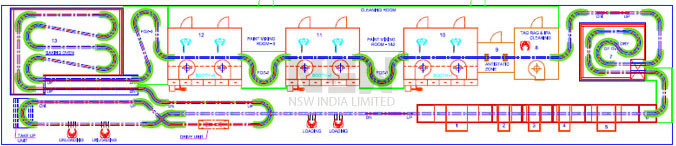

| Liquid Painting Plant with Spray P.T. Line |

![]()

|

|---|

| Line diagram for spray PT line with liquid painting plant |